In today’s world we need to guarantee equipment reliability. Equipment reliability is best defined as ensuring your equipment performs exactly how you want it to when you need it to. We need to shift away from reactive maintenance and figure out what needs to be done to keep equipment reliable.

In many industries there is a chronic problem with being unable to maintain equipment reliability. From our experience, many plants in North America are going through a maintenance cost paradox. As unscheduled maintenance issues arise, plants are under more and more pressure to reduce maintenance budgets thus causing more unscheduled downtime.

“Maintenance is a cost, reliability is an investment”

Our team can help you get out of the maintenance cost paradox by implementing the steps required to achieve world class reliability excellence.

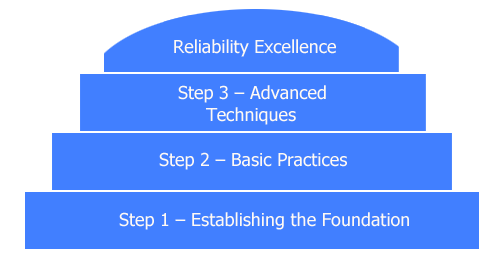

Steps for World Class Reliability Excellence

Step 1 – Establishing the Foundation

Would you build a house without a good foundation? The same logic applies for implementing a reliability process. In order to be successful implementing reliability best practices, you need to know what good looks like. You also need to ensure the right resources are available and that everybody is properly trained.

To establish the necessary foundation, we can help you with the following:

- Perform a reliability diagnostic and compare your plant to best practices

- Establish a clear 2 year reliability strategy for your plant based on the reliability diagnostic

- Provide reliability training so that operations and maintenance personnel are speaking the same language in terms of reliability practices

Step 2 – Basic Practices

Most plants in North America have over 65% of their maintenance technicians’ time tied up in delays and other non-value added activities. These delays and non-value added activities are not the fault of the technicians. They are the result of poor practices. Would you rather have your mechanics inspecting equipment and making adjustments or looking for spare parts? In order to reduce the non-value added time of your maintenance technicians the following basic practices need to be optimized:

- Work order entry

- Planning and scheduling

- Leveraging the computer maintenance management system (CMMS)

- Operator inspections

- Condition monitoring of equipment

- Management of spare parts

We have considerable experience and a unique approach at engaging hourly employees, supervisors and managers in workshops focused at improving the basic maintenance practices listed above.

Step 3 – Advanced Techniques

In order to obtain and sustain reliability excellence, advanced techniques such as Total Productive Maintenance (TPM) and Reliability Centered Maintenance (RCM) need to be implemented. However, if the reliability foundation and basic practices are not in place, it does not make sense to start with TPM and RCM.

Once you are ready, our professionals can help you go to the next level and implement the appropriate advanced reliability improvement technique.